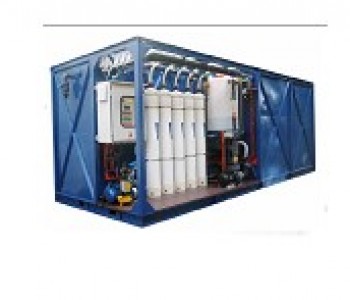

Membrane Bioreactor (MBR)

Membrane technology has led to a revolutionary new concept in wastewater treatment. Membrane Bioreactors (MBR) is an advanced treatment process used in wastewater treatment that combines biological treatment process with semi-permeable membrane technology. Membranes act as a barrier against bacteria and suspended solids to produce a low turbidity treatment plant effluent with very low bacterial counts. A Membrane Bioreactor (MBR) is a combination of a membrane process such as microfiltration or ultrafiltration with a suspended growth bioreactor. This very compact arrangement produces MF/UF quality effluent suitable for reuse applications or as a high quality feedwater source for Reverse Osmosis treatment. The energy demand of a submerged system can be up to 2 times lower than that of side stream systems, and submerged systems operate at a lower flow, demanding more membrane area. In submerged configurations, aeration is considered one of the main parameters on both hydraulic and biological process performances. Aeration keeps solids in suspension, cleans the membrane surface, and supplies the biomass with oxygen, leading to better biodegradability and cell synthesis.

Membrane Bioreactors (MBR) operate at solids retention times (SRT) as low as 10-20 days, resulting in more manageable mixed liquid suspended solids (MLSS) levels (10-15 g/L). Due to these new operating conditions, the oxygen transfer and pumping cost in the MBR is reduced and overall maintenance is simplified. Typical hydraulic holding times (HRT) range from 3 to 10 hours. In terms of membrane configurations, hollow fiber and flat sheet membranes are mainly applied for Membrane Bioreactor applications.

Considering that every technological development is an answer to a question, the most basic questions that come to mind for the birth of the MBR system are how to save space, how to increase the treatment efficiency and how to effectively recycle wastewater. MBR systems are systems with high chemical oxygen demand (COD) removal efficiency for wastewater that takes up much less space and has lower biodegradability compared to conventional biological treatment processes. Thanks to its small footprint, it is the biggest choice in regions where land costs are high.